High Consistency Continuous Pulping System

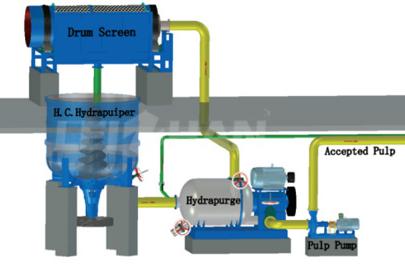

The high consistency continuous pulping system utilizes high-consistency pulping technology to efficiently crush and remove impurities from various types of waste paper under high-consistency (14-18%) conditions. This results in improved quality and processing efficiency of the waste paper, as well as enhanced pulp quality. The system is comprised of a high consistency hydrapulper, drum screen, and hydrapurger, all interconnected, screening, and discharging of waste paper raw materials.

Main Equipment Of High Consistency Continuous Pulping System

In the process of high consistency hydrapulping, waste paper is efficiently separated into individual fibers under high consistency and heat using a combination of mechanical and hydraulic shearing forces. This is accompanied by the introduction of chemicals like deinking agents, which aid in the removal of impurities such as ink particles that have been separated from the fibers.

In a high consistency continuous pulping system, the hydrapurger plays a key role in receiving the accept pulp from the H.C. Hydrapulper, it undergoes a roughing process within the hydrapurger, where impurities are separated from the accept pulp using a sieve plate.

The drum screen is positioned following the rough and is primarily utilized to carry out additional screening of the slurry.

Leizhan offers high consistency pulp equipment for pulping systems in high consistency conditions. Feel free to get in touch with us information. Contact us at leizhanworld@gmail.com.