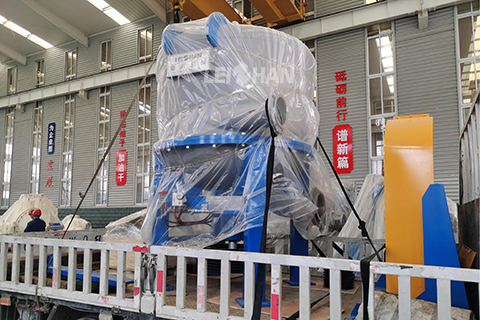

Light Impurity Separator For Paper Mill

The Light Impurity Separator is designed to efficiently remove unwanted impurities, such as plastics, metals, and other contaminants, from the pulp fiber stream. By separating these light impurities from the pulp, the separator helps maintain a clean and pure fiber stream, leading to higher-quality paper production. This not only improves the overall appearance and strength of the paper but also extends the lifespan of production equipment, minimizing downtime and maintenance costs.

Furthermore, the Light Impurity Separator plays a significant role in enhancing efficiency within the paper mill. By effectively removing impurities early in the production process, the separator prevents blockages and interruptions in downstream equipment, ensuring a smooth and continuous production flow. This results in increased productivity, reduced energy consumption, and ultimately, cost savings for the paper mill.

In addition to improving efficiency and quality, the Light Impurity Separator also contributes to the sustainability of paper production. By efficiently separating and removing impurities, the separator reduces the amount of waste generated during the production process, promoting environmental responsibility and resource conservation. This not only benefits the environment but also enhances the reputation of the paper mill as a responsible and environmentally conscious manufacturer.

With its proven ability to enhance efficiency, quality, and sustainability in paper production, the Light Impurity Separator has become an indispensable tool for modern paper mills. By investing in this advanced technology, paper manufacturers can achieve higher production efficiency, superior product quality, and a stronger competitive edge in the market. Embrace the future of paper production with the Light Impurity Separator and take your mill to new heights of success.

Email address: leizhanworld@gmail.com